Stamped Concrete

In Depth Ultimate Guide

This Stamped Concrete guide will answer the following questions:

- What Is Stamped Concrete?

- Why Stamped Concrete Will Add An Elegant, Jaw-Dropping Design Component To My Next Construction Project?

- How Stamped Concrete Is Made?

- What Options Are Available For My Stamped Concrete Project?

What Is Stamped Concrete?

- Is a solid anchor of the Decorative Concrete side of the Concrete Family and is above and beyond what one may typically think of when concrete comes to mind.

- Has all the strength, longevity and durability one associates with Concrete while having the innate ability to be a showroom to museum quality beautiful work of art. Right on your own property!

- The surface of freshly poured concrete is ‘Stamped’ to mimic wood, flagstone, tile, stone, brick, slate etc in vivid detail.

- Without the negative high maintenance, upkeep and hassle one endures with those other type of materials.

- No longer need to be concerned or worried with unlevel pesky pavers, weeds and or ants using the cracks in between to further their agenda!

- Unquestionably Adds Top Shelf Appeal To Your Home or Business.

- Multiple Stamp Patterns and Concrete Color options available to make a truly unique work of art!

Why Stamped Concrete Will Add An Elegant, Jaw-Dropping Design Component To Your Next Construction Project

- A sure fire way to make your property stand out from the rest of the neighborhood.

- Your neighbors, friends and family will definitely be impressed with your stamped concrete as it’s is a direct reflection of your style, tastes, personality & sophistication.

- The Bottom Line is…will make heads turn and jaws drop!

- You may be thinking, “Wow, if a Stamped Concrete can do this for my home, what can it do for my business?”

- For your business – whether an outdoor patio, dining area, entry way, bar area or wine tasting room subtly tells your clientele your place of business is well above and way beyond average.

- Whether it is a restaurant, winery or a retail business – strongly sends the message to your ideal client you are in the game for the long haul.

- Your investment in will readily return back to you many times over by making your ideal client’s experience be one of opulent, luxurious indulgence.

How Stamped Concrete Is Made

Pouring and Finishing Stamped Concrete is Similar to Regular Concrete With SEVERAL Additional Steps

- As with regular concrete – the sub grade, forming, re bar pinning where needed is still critical.

- Many factors influence the cost of your stamped concrete project.

- The layout of the area,

- Access to the area,

- The overall footprint of the project,

- Cost to fully wash the inside of the concrete mixer truck from the integral colors so as to not taint the next concrete delivery,

- Integral color costs,

- Release costs,

- Pattern selection,

- Overall design (i.e multiple patterns, colors involved).

- The above mentioned are a few of the legitimate factors which will be involved in the final cost associated with your stamped concrete project.

- The concrete mix changes for stamped concrete by utilizing a smaller aggregate.

- The smaller aggregate is used to make sure that all areas of the stamped concrete pour is uniform.

- The uniformity keeps the slab strong and consistent for years of beautiful enjoyment.

- Integral Concrete Color is mixed with the redi-mix concrete batch to color the concrete throughout the concrete mix.

- This is usually done on site when the concrete mixer truck arrives. But it can also be done at the concrete plant at the time of dispatch.

- Once the concrete has been poured, screed and floated; color release powder is broadcast across the surface of the concrete to be stamped before the stamping of the concrete starts.

- This release is similar to flour when making biscuits in that the release allows the stamp to be removed from the concrete while leaving the concrete surface in tact.

- A Concrete Finisher (Cement Mason) sets a large, heavy rubber pattern on top of the concrete surface to be stamped.

- Then tamps to emboss the pattern from the stamp into the surface of the poured concrete mix.

- The stamp patterns are placed side by side careful not to drag, dig or otherwise touch the concrete surface until in the exact location the concrete finisher wants them.

- This process continues in a steady process from start to finish.

- Usually there is one person responsible for texturing and grooving the edges of the concrete that the patterns don’t stamp well enough.

- The concrete stamps do not stamp as deep along the home or structure – the concrete stamps will not completely unfold.

- Along the edges next to the forms because the top of the wood or metal form doesn’t allow deep enough embossing of the stamp.

- All the edges have to completed by hand to assure an authentic look.

- Any groove or texture from the stamp itself is pressed into the concrete surface. This results in a nice color contrast between the main concrete color and the accents.

- Once the stamping process is complete the concrete is allowed to cure.

- Typically, the expansion joints will be saw cut followed by a light power washing to remove excess release.

The concrete is allowed to dry overnight and then the Concrete Sealer will applied.

What Options Are Available For Your Stamped Concrete Project

Whether your concrete is uniform across the entire project with one pattern or several stamped concrete ‘piece’ components are part of an overall design, each are considered an individual .

A Selection Is to Be Made From The Following Three Categories:

- Category 1 – Stamp Pattern | To Stamp The Surface Of Your Concrete With

- Category 2 – Integral Color | To Be Mixed Within Your Concrete To Be Stamped (Natural Concrete Color Is An Option!)

- Category 3 – Release Color | For The Highlights And Indentations Of Your Stamped Concrete

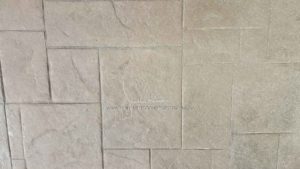

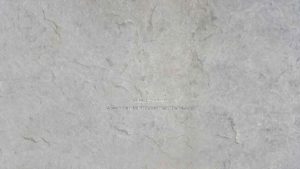

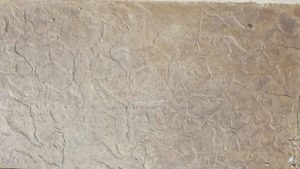

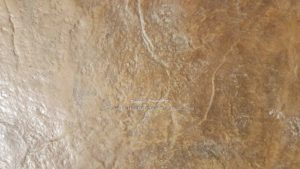

Category 1 – STAMP PATTERN

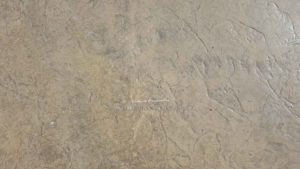

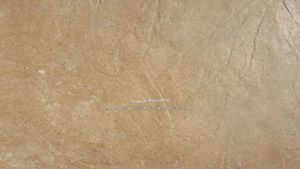

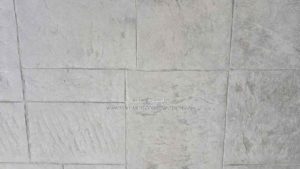

Choose The Stamp Pattern To Stamp The Surface Of Your Concrete With:

(Click to Enlarge)

Appian Cobble Stone

Arizona Flagstone

Ashlar Slate

Ashlar Slate 2

Chiseled Slate

Chiseled Slate 2

English Ashlar

European Fan

Forest Floor

Heavy Stone

Italian Slate

Majestic Ashlar

Oxford Slate

Random Sandstone Hammered Edge

Random Sandstone Hammered Edge 2

Running Bond Used Brick

Sidewalk Slate

Category 2 – INTEGRAL CONCRETE COLOR

Choose The Integral Butterfield Concrete Color:

(This will be the overall color of your concrete)

Integral Color Chart 1

Integral Color Chart 2

Integral Color Chart 3

Category 3 – RELEASE COLOR

Choose The Color For Your Highlights and Indentations

Butterfield Release Color:

Butterfield Antiquing & Release Agents

Questions About Stamped Concrete Or If Can Be Of Further Assistance Get In Touch Via The Form Below

Stamped Concrete Is Great For a Wide Range of Residential and Commercial Applications:

-

Residential Applications:

Basements

Carports

Driveways

Foyers

Garages

Kitchens

Living Rooms

Patios

Pool Decks

Porches

Sidewalks

Outdoor Kitchens

-

Commercial Applications:

Arenas

Bathrooms

Churches

Classrooms

Driveways

Garages

Hotel Entryways

Kitchens

Lobbies

Patios

Plazas

Pool Decks

Restaurants

Retail Stores

Shopping Centers

Showrooms

Sidewalks